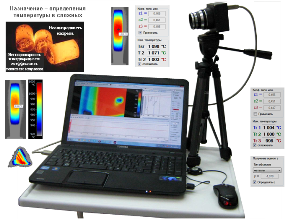

Optical gauge of temperature IT-3SM

Purpose

PurposeThermal imager IT-3 SM is intended for non-contact detection and visualization of the temperature field of the hot bodies visible surface

Characteristics

Imager consists of a standard notebook computer and the special digital video block recording thermal radiation in three overlapping spectral regions in the range of 630–830 nm. SVGA-matrix of photodetectors MT9V034STC with the number of active elements 752×480 is used. If necessary, measured temperature range can be extended up to 3000 °C.

Technical characteristics:

| Parameter name | Value |

| Measured temperature range, °С | From 800 to 1700 with possibility to extend up to 3000 |

| The least significant display digit of measured temperature, °С | 1 |

| Limits of permissible absolute error of temperature measurement, °C | ± 5 |

| Used photodetector | SVGA-matrix of photodetectors with the number of elements 752×480 |

| The spectral range in which the thermal radiation is recorded, um | 0.63–0.83 |

| The aperture value of the lens used at the temperature measurement | 16 |

| Displaying of the recorded temperature field | On the monitor as a color palette image with vertical color scale of temperature values |

| Measured temperatures | Partial radiation temperatures, the spectral ratio temperature; when taking into account "E" values, the actual temperature is determined |

| Frequency of frames, Hz | Tunable from 1 to 30 Hz |

| Values output period T max, sec | 0.5 |

| Option of regression smoothing of the obtained temperature values | Yes |

| Option of approximate determination of the effective thermal emissivity | Yes |

| Video block supply voltage, V | 5 ± 10% (from USB port) |

| Video block consumption power, W, not more | 5 |

Functional features:

– a single temperature measurement range from 800 to 1700 °C without subbands

– screening of color image of the temperature field with the rate up to 30 frames/sec

– option of the automatic determination of the effective thermal emissivityes of the surface in the used spectrum regions

– possibility of recording the temperature field of the arranged heat engineering process and its reproducing, which is convenient while minimizing heating energy consumption, as well as while the following periodic inspection

– reduced influence of the cooling liquid vapor, which can get into the field of view during the quenching process control, on the measured temperature values, that is provided by the smoothing of the obtained temperature values by means of regression methods

– the possibility of registering and video recording the pulsed heating processes with block-by-block search

Foreign counterparts: Pyrovision M9103 and M9104

Application

engineering

Condition of production

Products under the order